Does My Business Need Both ISO 9001 and ISO AS9100?

In the aerospace industry, having a strong Quality Management System (QMS) is crucial. A robust QMS certified to ISO 9001 can help deliver safe, reliable products and services that meet strict industry standards.

However, QMS certification isn’t just about compliance. Having the right certification can make a big difference to your business. It can open doors to new business opportunities and help demonstrate your commitment to excellence.

For aerospace manufacturers and suppliers, understanding how the quality management standards ISO 9001 and AS9100 work together can provide a strategic advantage that can help their company grow.

Over 26,800 ISO 9001 certifications have been awarded in the US, indicating its popularity across various industries. But if you’re in the aerospace industry, you might wonder whether you need both ISO 9001 and AS9100.

According to the Online Aerospace Supplier Information System (OASIS), there are over 10,000 AS9100-certified sites in the US, as of June 30, 2025. With many aerospace prime contractors now requiring AS9100 certification from their suppliers, this expectation is likely to become even more widespread.

“While AS9100 certification isn’t a formal requirement in every case, we’re seeing it become a key differentiator,” says Tom Droog, Aerospace and Automotive Scheme Manager at Amtivo. “Holding the certification can signal to aerospace customers that your business meets the highest quality and safety standards—and that can influence supplier selection.“

As the market leader in aerospace certification in the US, Amtivo can help. Read on to learn more about both standards, their differences, and whether having both can benefit your business.

What Is ISO 9001?

ISO 9001 is the world’s most widely adopted quality management system standard. It helps organizations deliver consistent product and service quality while meeting customer and regulatory requirements.

ISO 9001 is relevant to businesses of any size and industry. For companies in the aerospace industry, ISO 9001 could be considered a good first step before progressing to AS9100 certification.

While the ISO 9001 standard is valuable across all industries, it doesn’t address industry-specific requirements. This is where specialized standards like AS9100 come into play.

What Is AS9100?

AS9100 is an internationally recognized quality management system standard specifically designed for the aerospace industry. Governed by the International Aerospace Quality Group (IAQG), AS9100 builds upon ISO 9001 by adding requirements that address the complexities and risks unique to aerospace manufacturing and supply chains.

“Think of AS9100 as ISO 9001, plus aerospace-specific requirements,” explains Tom Droog. “It includes everything in ISO 9001, then adds layers of requirements that address the unique challenges of aerospace production, like configuration management, risk management, and product safety.”

While AS9100 isn’t technically mandatory, it has become a de facto requirement for doing business with major aerospace manufacturers like Boeing, NASA, Lockheed Martin, Honeywell, and Northrop Grumman. Many of these prime contractors will only consider suppliers with AS9100 certification, making it essential for companies looking to enter or expand within the aerospace supply chain.

The Relationship Between ISO 9001 and AS9100

Here’s the critical point that many businesses overlook: AS9100 fully incorporates ISO 9001. This means that when your organization achieves AS9100 certification, you’re simultaneously meeting the requirements of ISO 9001.

AS9100 enhances the foundational quality management system requirements of ISO 9001 with additional requirements specific to aerospace. Both standards share the same high-level structure, making integration straightforward.

That means, if your aerospace business already has ISO 9001, you’re ready to move towards AS9100. In fact, you’re already more than halfway there.

Getting AS9100-certified can help you win more business as a supplier in the aerospace industry.

What Are the Differences Between Them?

ISO 9001 and AS9100 are both quality management system standards, but differ slightly in scope and focus.

ISO 9001 works for any type of business in any industry. It focuses on customer satisfaction, leadership and continual improvement.

AS9100 is specifically for aerospace companies. It includes everything from ISO 9001 plus extra requirements. These cover risk management, controlling product specifications and product safety, which are key for aerospace safety and quality.

Here are the key differences between ISO 9001 and AS9100:

|

Aspect |

ISO 9001 |

AS9100 |

|---|---|---|

|

Scope |

Applicable to any industry. |

Specific to the aerospace industry. |

|

Focus |

Focuses on customer satisfaction, leadership, and continual improvement. |

Includes ISO 9001 focus plus additional aerospace-specific needs. |

|

Additional Requirements |

None specific beyond ISO 9001. |

Adds configuration management, risk management, and product realization for aerospace. |

|

Industry Need |

Suitable for general industries. |

Essential for compliance and reliability in aerospace manufacturing and services. |

|

Pathway for Certification |

Provides a foundation for quality management. |

Offers a pathway to achieve both general and aerospace-specific quality standards. |

|

Adoption Process |

Straightforward for most industries. |

Requires adopting additional requirements for those moving from ISO 9001 to excel in aerospace. |

Read our full guide to the differences between ISO 9001 and AS9100.

Which AS9100 Clauses Are the Same As ISO 9001?

AS9100 maintains the same clause structure as ISO 9001, with both standards organized around these key sections.

- Scope

- Normative references

- Terms and definitions

- Context of the organization

- Leadership

- Planning

- Support

- Operation

- Performance evaluation

- Improvement

Within these clauses, the core requirements of ISO 9001 remain intact in AS9100. If you’re already ISO 9001-certified, you’ve already implemented and demonstrated compliance with a significant portion of AS9100’s requirements.

What Are the Additional Requirements of AS9100?

AS9100 builds upon ISO 9001 by adding aerospace-specific requirements throughout the standard.

Some of the key additions include:

Product safety

AS9100 adds requirements for managing product safety throughout the product lifecycle, including identifying critical items and implementing special controls.

Prevention of counterfeit parts

With counterfeit parts posing a significant risk in aerospace, AS9100 requires processes to prevent the use of counterfeit or suspect counterfeit parts.

Configuration management

AS9100 requires a more robust configuration management approach, including identifying and controlling physical and functional attributes throughout the product lifecycle.

Risk management

While ISO 9001 includes risk-based thinking, AS9100 requires a more formalized approach to risk management across all business processes.

Special requirements and critical items

AS9100 adds requirements for identifying and managing special requirements, critical items, and key characteristics.

Product realization

AS9100 expands on product realization processes, requiring more detailed planning and control over product design and development. This includes thoroughly understanding customer requirements and checking that all products meet them.

Awareness

AS9100 expands awareness requirements to include product safety, ethical behavior, and the importance of individual contribution to quality.

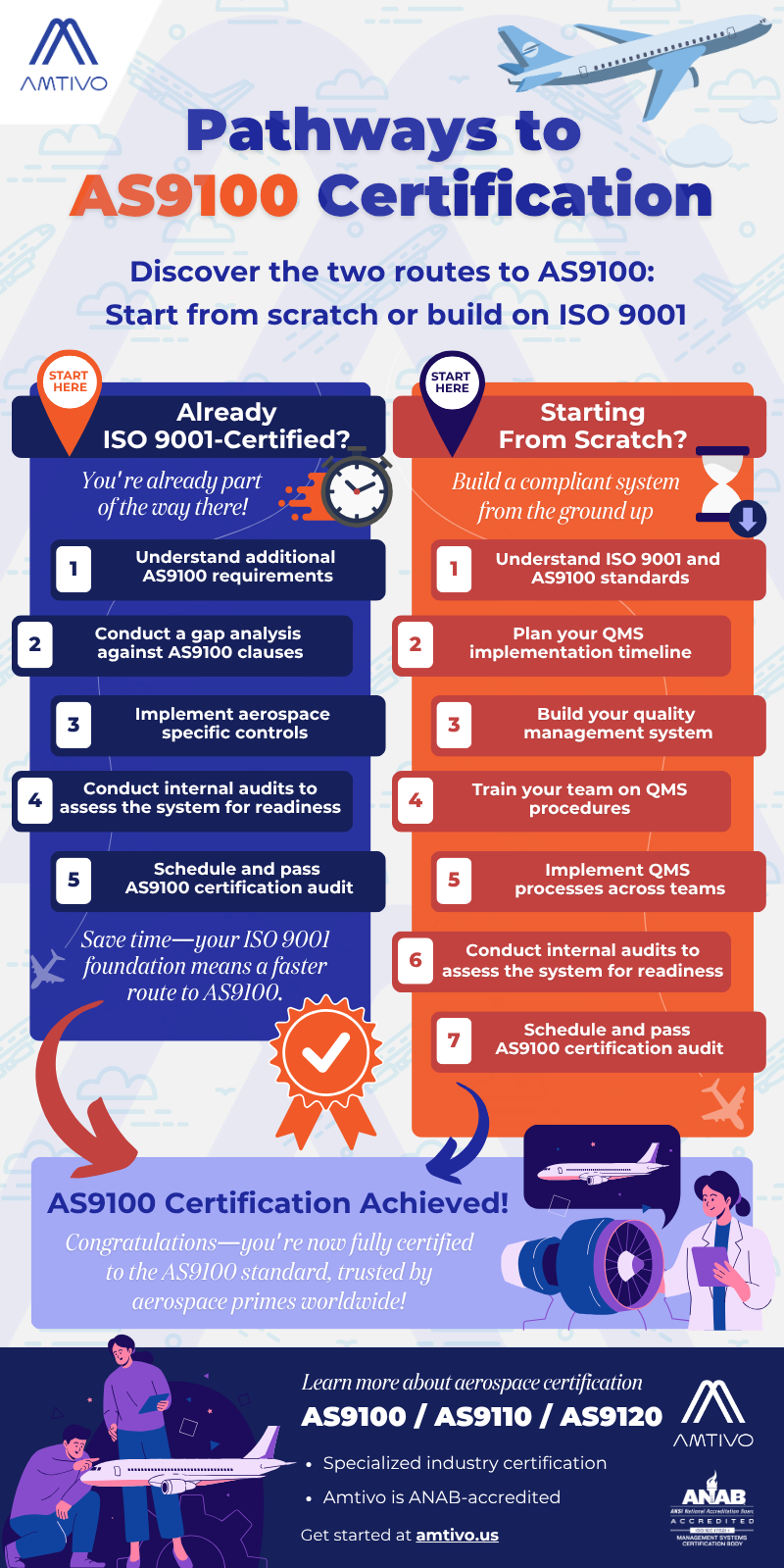

Path 1: Transitioning to AS9100 From ISO 9001

If your organization is already ISO 9001-certified, you’re in an excellent position to pursue AS9100 certification.

“Many organizations are surprised by how much of their existing ISO 9001 system directly transfers to AS9100,” notes Tom Droog. “The key is understanding the additional aerospace requirements and how they build upon your existing quality management system.”

Here’s the typical transition process:

1. Understand the AS9100 requirements

It’s best to start by thoroughly understanding the additional requirements of AS9100, like risk management and configuration management.

This may mean obtaining a copy of the standard and potentially seeking training or consultation to understand the aerospace-specific elements.

2. Conduct a gap analysis

A detailed gap analysis should be performed to identify which AS9100 requirements are already satisfied by your ISO 9001 system and which require additional implementation. This analysis will form the foundation of your AS9100 implementation plan.

3. Implement changes

Based on your gap analysis, implement the necessary changes to your quality management system. This typically involves:

- Updating your quality manual and procedures

- Developing new processes for aerospace-specific requirements

- Enhancing existing processes to meet the more rigorous aerospace standards

- Training staff on the new requirements

- Updating documentation to reflect the expanded scope

4. Prepare for audit

Before certification, organizations are required to conduct a thorough internal audit against AS9100 requirements. This helps identify any remaining gaps and provides an opportunity to correct them before the formal certification audit.

5. Certification audit

Work with an accredited certification body, like Amtivo, to schedule and complete your AS9100 certification audit. As you’re already ISO 9001-certified, this process will focus primarily on the aerospace-specific requirements.

6. Maintain AS9100 certification

After achieving AS9100 certification, you should maintain your system through internal audits, management reviews, and continual improvement. Your certification body will conduct surveillance audits annually to ensure ongoing compliance.

Path 2: Starting from Scratch—Pursuing AS9100 Without Prior ISO 9001

If your organization doesn’t currently hold ISO 9001 certification, you can pursue AS9100 directly. This approach is often more efficient for aerospace businesses, as it allows you to implement one comprehensive system rather than taking a two-step approach.

“For aerospace suppliers starting from scratch, going directly to AS9100 is almost always the most efficient path,” says Tom Droog. “You’ll be implementing all the ISO 9001 requirements as part of AS9100, so there’s no reason to pursue them separately.”

The implementation process for organizations without existing certification typically includes:

1. Develop understanding

Organizations will learn about both ISO 9001 and AS9100 requirements, recognizing that both will be implemented simultaneously as part of the AS9100 standard.

2. Plan implementation

Organizations create a comprehensive implementation plan that addresses all aspects of the standards, starting with the foundational ISO 9001 elements and building up to the aerospace-specific requirements.

3. Build Quality Management System

The quality management system will be developed and documented, including a quality manual, procedures, work instructions, and forms. This system will address both the general quality requirements from ISO 9001 and the aerospace-specific requirements from AS9100.

4. Train teams

Organizations will ensure all employees understand their roles in the QMS and provide appropriate training on both general quality principles and aerospace-specific requirements.

5. Implement the system

The QMS will be put into practice, allowing sufficient time for it to generate records and demonstrate effectiveness.

6. Conduct internal audits

Internal audits will be performed to verify that the system meets all AS9100 requirements and identify opportunities for improvement.

7. Certification audit

Organizations will work with an accredited certification body to schedule and complete the AS9100 certification audit.

Making the Decision: Is AS9100 Right for Your Business?

Whether you’re starting with ISO 9001 or from scratch, pursuing AS9100 certification represents a significant investment in your organization’s future. Here are some considerations that may help you decide if it’s the right move:

If you already have ISO 9001:

- Do you currently serve aerospace customers or plan to in the future?

- Are you losing opportunities because you lack AS9100 certification?

- Have your existing customers indicated a preference or requirement for AS9100?

- Do you want to differentiate your business in the marketplace?

“We often see ISO 9001 certified companies hit a ceiling in the aerospace market,” explains Tom Droog. “They can only grow so far without AS9100, regardless of their capabilities or quality. Making the transition opens up entirely new tiers of opportunity.”

If you’re starting from scratch:

- Is aerospace a primary target market for your business?

- Will your products or services be used in aerospace applications?

- Do you want to position your company for maximum opportunity in aerospace supply chains?

- Are you looking to implement a quality management system that will serve both general and aerospace-specific needs?

Taking the Next Step

Amtivo has extensive experience in aerospace certification, helping organizations navigate the certification process with confidence.

By understanding the relationship between ISO 9001 and AS9100 and choosing the path that best fits your organization’s starting point, you can efficiently achieve certification and unlock new opportunities in the aerospace supply chain.

Ready to explore AS9100 certification for your business? Contact Amtivo today to speak with our aerospace certification specialists and discover how we can support your certification journey.